Views: 0 Author: Site Editor Publish Time: 2025-12-30 Origin: Site

A flawless paint job is the ultimate signature of a quality auto body shop. While customers marvel at the glossy finish and perfect color match, professionals know the real work happens long before the spray gun trigger is pulled. The secret to a pristine finish often lies in the preparation, specifically in how the vehicle is masked.

Overspray, bleed-through, and adhesive residue are the nightmares of any collision repair technician. Correcting these errors costs time, money, and reputation. That is why selecting the correct masking materials is not just a purchasing decision—it is a technical necessity. From dealing with high-heat baking cycles to covering large SUVs quickly, the right film or tape can define the success of a project.

This guide explores how professionals navigate the options to find the best solutions for their shop.

Why can't a shop just use standard plastic sheeting or generic tape? The environment inside a spray booth is hostile to ordinary materials. Between the chemical solvents in modern basecoats and clearcoats, and the intense heat used in curing ovens, standard supplies will fail.

Professional Masking Materials for Automotive Spray Paint are engineered to specific standards. If a shop chooses the wrong material, three things usually happen:

Paint Flaking: The overspray dries on the plastic, flakes off, and lands in the wet clearcoat on the car.

Bleed-Through: Solvents penetrate the paper or film, staining the surface underneath.

Adhesive Transfer: The tape melts during the bake cycle, leaving a sticky mess that requires hours of buffing to remove.

Efficiency is the other major factor. The goal is to mask a car as quickly as possible without sacrificing protection.

Shops generally keep both on hand, but they serve different purposes. Choosing between them depends on the size of the area being covered and the type of paint being used.

Masking Paper is traditional. It is thick, absorbent, and great for masking the immediate perimeter of the repair area. It handles the heavy edge of the spray fan well. However, it is heavy, can be dusty (lint), and is inefficient for covering an entire car.

Masking Film is the modern standard for total vehicle protection. It is lightweight, static-charged to cling to the car, and allows light to pass through.

Here is a quick comparison of how shops decide which to use:

Feature | Masking Paper | Masking Film |

|---|---|---|

Coverage Area | Small to Medium (Windows, Bumpers) | Large (Full Vehicle, Hoods, Roofs) |

Portability | Heavy rolls | Lightweight, folded rolls |

Overspray Holding | Good (Absorption) | Excellent (Electrostatic adhesion) |

Dust/Lint | Potential for paper fibers | Lint-free |

Cost Efficiency | Lower cost per roll, higher cost per foot | Higher upfront, cheaper per square foot |

In modern collision repair, speed is everything. To speed up drying times, most shops use heated spray booths or infrared curing lamps. This heat can destroy standard plastic films. This is where High Temp Resistant Masking Film becomes non-negotiable.

Standard construction-grade plastic will melt or warp at around 140°F (60°C). However, automotive baking cycles frequently exceed this. A professional body shop will look for HighTemperature Resistant Masking Film that meets specific thermal criteria.

According to industry standards, high-performance films should handle the following thermal loads:

Temperature Exposure | Duration | Application Context |

|---|---|---|

180°C (356°F) | Up to 30 Minutes | Standard Baking Cycles / Spray Booths |

200°C (392°F) | Short Term | Infrared Curing / Spot Heating |

If a technician knows the car is going into the oven, they must verify the temperature rating of the film. Using a film with high heat resistance ensures that the plastic remains intact and does not fuse to the vehicle's bodywork.

Beyond heat resistance, what makes a masking film "good"? Professionals look for specific technical properties that make the job easier and safer.

Paint Adhesion (Corona Treatment): You do not want the paint that hits the plastic to run off or flake. High-quality masking films are treated chemically (often called Corona treatment) to ensure paint overspray sticks to the film. This prevents dried paint chips from fluttering off the plastic and landing in your fresh clearcoat.

Paint Penetration Prevention: The film must be dense enough that solvents and waterborne paints cannot soak through to the car panel beneath.

Tear Resistance: The film needs to be strong. Technicians pull, stretch, and tape these films quickly. Good tear resistance keeps the film intact during the masking process, preventing accidental exposures.

Static Cling: The best films are statically charged. This allows the film to "snap" to the vehicle body, holding it in place while the technician applies tape. It also helps trap dust particles that might otherwise end up in the paint.

Time is the most valuable resource in a body shop. tearing off tape, applying it to the car, and then wrestling with a sheet of plastic is a multi-step process. To solve this, manufacturers have developed 2-in-1 solutions.

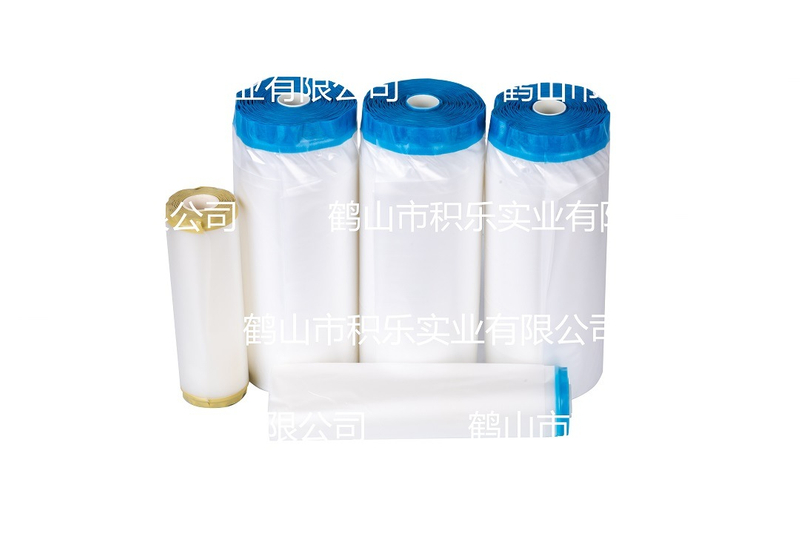

These products come with the tape already attached to the edge of the masking film. This allows a technician to unroll the film and tape the edge simultaneously.

For example, the Roller Masker 2-in-1 Solution of Tape And Non-Adhesive Film is designed specifically for this purpose. It combines the adhesion required for sharp paint lines with the protection of a film, drastically reducing setup time.

Benefits of 2-in-1 Masking Solutions:

Speed: Cuts masking time by up to 50% for large areas.

Simplicity: Requires only one person to apply, even on large windows or hoods.

Consistency: The pre-attached tape ensures a straight edge every time.

It might seem counterintuitive to spend more on premium masking materials like High Temp Resistant Masking Film when cheaper alternatives exist. However, experienced shop owners view masking as an insurance policy.

Consider the cost of failure. If a cheap plastic film melts onto a hood during a bake cycle, the shop has to:

Sand down the damage.

Re-prep the surface.

Re-mask the car.

Re-paint and Re-clear.

That rework cost includes labor, materials, and lost booth time—far exceeding the few dollars saved on a roll of cheap plastic.

By utilizing masking films that offer high temperature resistance (180°C for 30 mins) and excellent paint overspray adhesion, shops prevent these disasters. The film stays intact, the paint doesn't flake, and the car comes out of the booth ready for delivery, not rework.

Choosing the right masking materials is about matching the product to the process. For quick primers or small spot repairs, masking paper might suffice. But for full resprays, baking cycles, and high-end finish work, investing in quality Masking Materials for Automotive Spray Paint is essential.

Technicians should prioritize materials that offer:

Confirmed temperature resistance (up to 200°C for short bursts).

Electrostatic properties for dust control.

Proven resistance to paint flaking and bleed-through.

By focusing on these technical specs, auto body shops ensure faster turnaround times and happier customers.